Model Based Systems Engineering (MBSE) for Aerospace

5-step plan to get started with or improve MBSE capabilities

scroll down

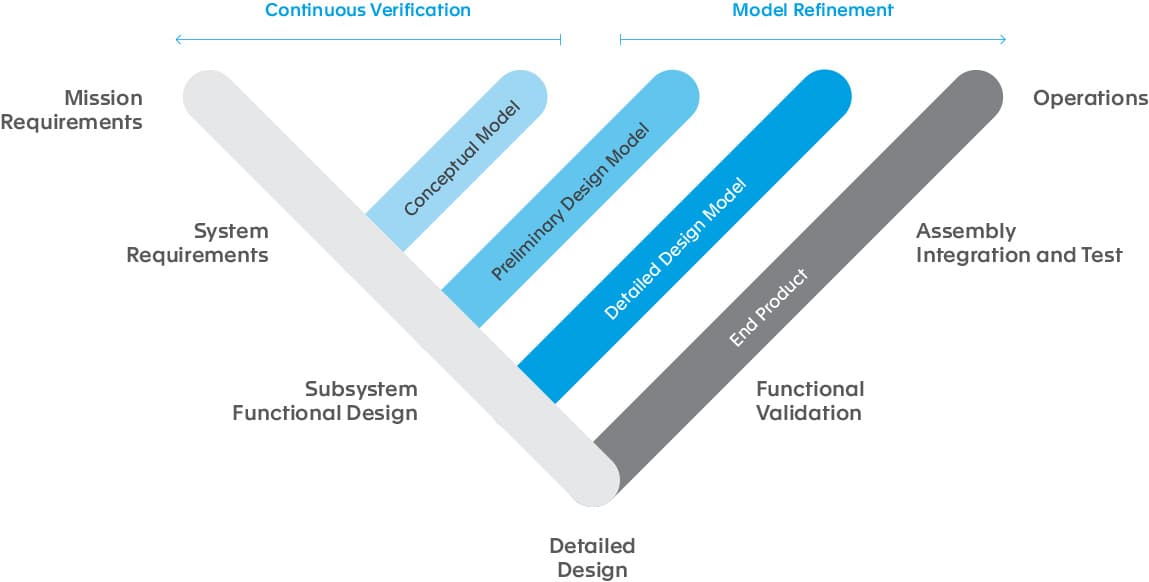

The introduction of digital tools into the engineering process of complex systems has enabled significant enhancements all along the design and production phases of such products. One of the paradigms of the new methodologies being implemented is the centralized source of information to gather the data needed along the product lifecycle. Another paradigm of these modern methodologies is the automated verification; implementing queries and tests to verify that the system complies with the objectives set by the different stakeholders.

Leveraging on digital technologies, the state-of-the-art tools being used in the industry allow to master the flows of information between stakeholders, resulting in an overall gain of quality and a reduction of human effort in engineering tasks.

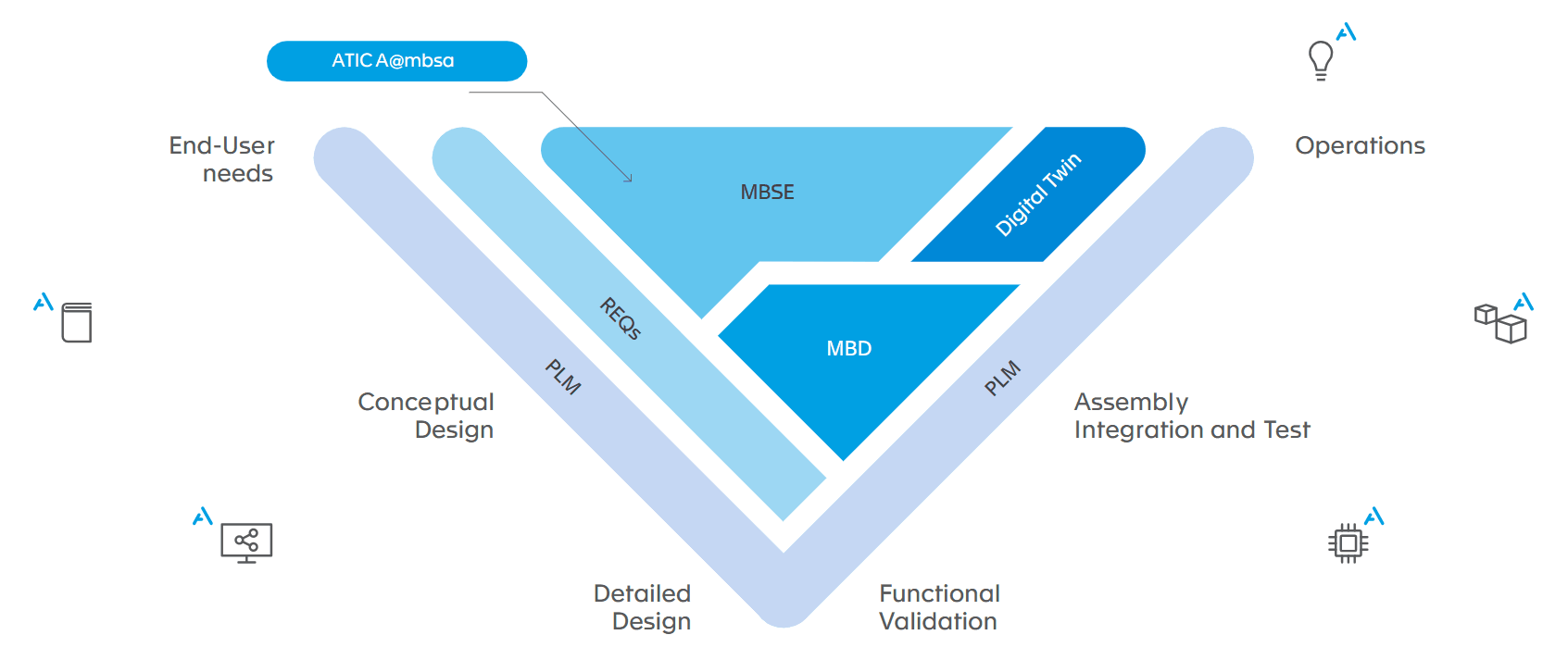

Our MBSE & MBSA solutions consists of a methodology and a combination of tools implementing a model-based engineering approach to develop complex safety-critical systems, from the conceptual design up to the final verifications. Based on the two aforementioned paradigms; our method extends the architectural model of the system with a new perspective that allows to introduce the safety data and to run automated analysis aligned with the typical normative standards.

Our model-based solutions benefit from the experience gained throughout multiple years collaborating with the main stakeholders in the aerospace industry and other sectors developing safety-critical systems.

| Systems | Electronics | Embedded Software | |

| (Model Based) Systems Engineering | Concept of operations (CONOPS), use-cases, architectures, functional breakdown | Architecture diagrams, modeling & simulation, ICDs | Model Based Design, Automatic code generation |

| Safety | Functional Hazard Analysis (FHA), Fault Tree Analysis (FTA), Cut Sets | Failure Mode and Effects Analysis (FMEA) | Formal verification, Model checking |

| Dependability (Reliability, Availability, Maintainability) | Reliability Block Diagrams, Failure Modes and Effects Summary (FMES) | Derating Analysis, Reliability Prediction, FMECA | Code coverage, IP verification, Markov chains |

| Failure Detection, Isolation and Recovery (FDIR) | Ground-board interaction, systems of systems | Detectability, Isolation | Hardware-Software Interaction Analysis (HSIA) |

| Step | Tasks and activities | |||

|---|---|---|---|---|

Gap Analysis |

| |||

Implementation |

| |||

Modeling & Simulation |

| |||

Tailoring |

| |||

|

Whether it is for modelling complex systems or for developing advanced MBSE extensions, our team can help adapting existing tools and frameworks to your domain-specific processes.

| Our tool ATICA aims at collecting all the Safety and Reliability related data in a unique platform shared with systems engineers ensuring consistency across the design and verification processes of complex systems. | ATICA works in several layers: Product architecture System and subsystem Component | Each layer collects the necessary information, both high and low level, considering the project requirements in order to collect the required evidence and produce the demonstrations needed by end users and authorities to get an aerospace certification. |

ATICA provides solutions along the whole V-Cycle, making the development phase easier and reducing development costs. It also keeps the end-to-end traceability, making systems-safety analysis simpler.