scroll down

The certification processes of highly complex systems such as those developed in the aerospace, defense or eVTOL industries, among others, must comply with rigorous standards..

Certifications can be divided in analytical and experimental methodologies such as validation tests and RAMS assessments (Reliability, Availability, Maintainability and Safety).

In Anzen we focus on RAMS, providing the most valuable engineering services to our customers.

Our mission as a specialized engineering firm is to provide the best quality and flexible solutions to our customers.

For that reason, our team is composed of the best professionals in each area of System Safety & Reliability.

- European leaders in aerospace RAMS engineering

- World-class team of 30 RAMS engineers

- Participating in the most relevant

aerospace projects - Global company: Customers worldwide

(USA, France, UAE, Switzerland, UK…) - Local presence in the US, Switzerland, UAE and

Spain.

scroll down

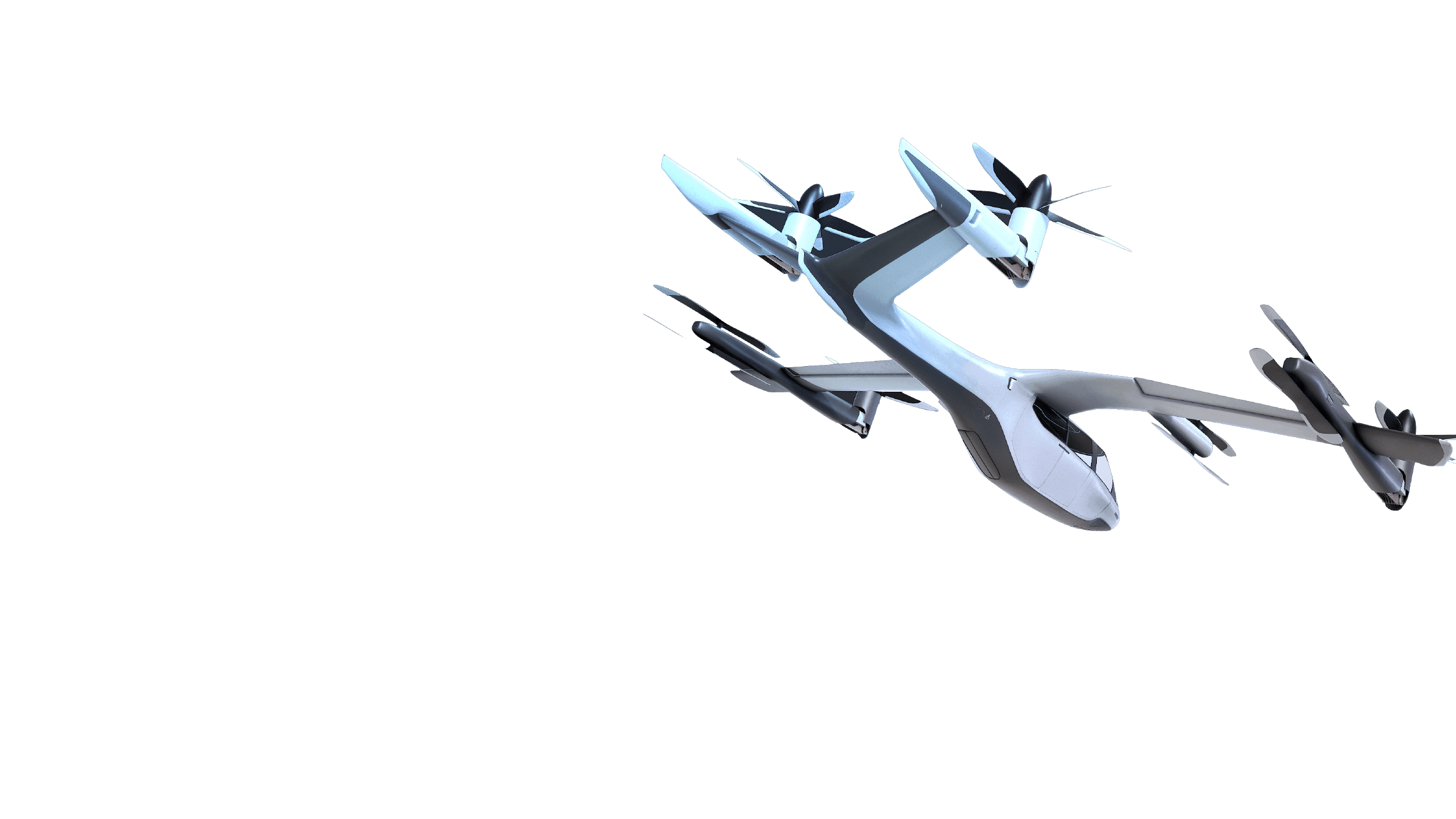

Our company is a leader in RAMS in eVTOL engineering, with deep expertise in unmanned systems and rotor aircraft. We offer comprehensive solutions to ensure efficient and safe eVTOL vehicle operation.

With extensive experience in hybrid, distributed, and electric propulsion, our team of experts is uniquely equipped to provide cutting-edge solutions for eVTOL RAMS. We are committed to advancing the state-of-the-art in this field, shaping the future of eVTOL technology through our expertise in aviation, aerospace and systems engineering.

Safety challenges that are unique to eVTOLs

Electric propulsion: While electric propulsion offers many benefits, it also presents some safety challenges. For example, the high energy density of batteries requires careful handling to prevent thermal runaway or fires. There is also a risk of electric shock during maintenance or repair.

Multiple rotors: eVTOLs typically have multiple rotors or propellers, which must be carefully designed and maintained to prevent failures that could lead to an accident.

Autonomy: Some eVTOL designs rely on autonomous systems to fly and navigate, which raises concerns about the reliability and safety of these systems.

Urban environment: eVTOLs are designed for operation in urban environments, which presents unique safety challenges, such as avoiding collisions with other vehicles or buildings

scroll down

We are focused on, but not limited to, the following activities:

Do you know how to develop and implement your Safety Program Plan?

The purpose of a Safety Plan is to specify the managerial and technical tasks that should be accomplished to assess the design safety of the product under certification.

It describes how the safety tasks will be managed and how to provide all the necessary information and evidence to ensure the development and delivery of the system within an acceptable level of risk.

This plan defines the scope of the system safety activities and the deliverables planned for the project, including the safety objectives, organization, and responsibilities. It also provides details of the safety assumptions and a general overview of all safety related activities to be performed.

scroll down

The complexity of the operational approval process increases dramatically as the intrinsic risk of the operation (low, medium or high) increases. The required level of robustness for any risk mitigation or operational safety objective is linked with such intrinsic risk.

Within the “Specific” category, the applicant of an operational approval request must collect and provide the relevant technical, operational and system information needed to assess the risks associated with the intended operation of the UAS. The SORA process provides the framework for the assessment of such risk by a logical process to analyze the proposed Concept of Operations, or CONOP, and establish an adequate level of confidence that the operation can be conducted with an acceptable level of risk. Within the SORA process, the Specific Assurance and Integrity Levels (SAIL) drive the robustness of the operational safety objectives (OSO).

For medium risk, compliance with EASA SC Light UAS.2510 and 2511 a can be performed through a relevant safety analysis such as “UAS level FHA” and a “Loss of Containment analysis” to identify failures and combination of failures which could lead to operations outside the operational volume.

Key aspects to perform a Loss of Containment Analysis

For medium risk UAS, regulators are considering the use of extensive evidence from functional tests among the means of compliance with loss of control of operations. However, the amount of hours required for this extensive testing (in the order of 3,000 hours for SAILIII) might require a huge effort and time. An alternative which can be proposed is either complementing or replacing such testing by a safety analysis aimed to show that the loss of control of operation meets the regulator’s expectations. This might be achieved by the use of FHA techniques (at UAS level or system level) to identify the failures and combination of failures that could lead to loss of control of operation, along with qualitative and/or quantitative Fault Tree Analysis and Common Mode Analysis.

scroll down

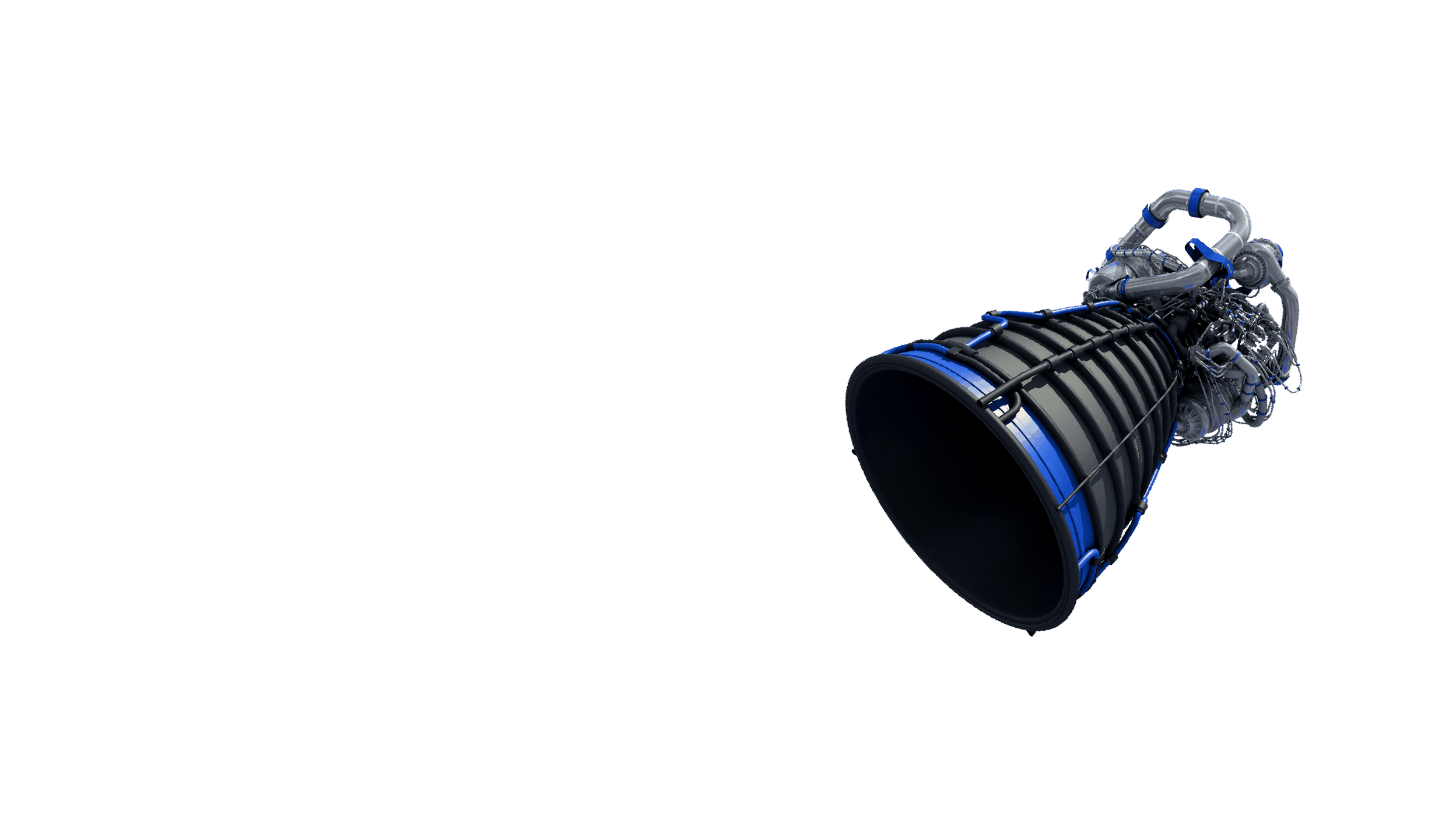

We are also getting ready for new mission concepts, reinforcing our capabilities in areas such as:

- Reliability: tailoring analysis for COTS (commercial-off-the-shelf), especially suited for New Space companies and disruptive mission concepts.

- Availability: space-based infrastructure providing critical services for our daily activities (communications, GNSS, natural catastrophe protection…).

- Maintainability: new mission concepts featuring on-orbit servicing and on-orbit assembly, with possibility to replace faulty and obsolete components.

- Safety: especially relevant for manned missions (including the upcoming initiatives of space tourism and outer space exploration.

Our services help ensure the long-term sustainability of space activities, extending the operating lifetime of space vehicles and guaranteeing the safe and reliable operation of space assets up to the end of the mission (including decommissioning and deorbiting).

The concept of Safe Missions

From the ground segment to the space systems, the space sector is increasing the effort devoted to system safety.

A space system can be developed over the course of more than twenty years, investing large amounts of money in engineering and manufacturing.

Despite the fact that many of the space missions are unmanned and they do not represent a risk for humans, they often have a high economic risk.

For that reason, the industry is being aligned with aeronautics by redefining safety as a critical factor.

scroll down

Our heritage in leading defense programs makes Anzen the best partner to assess and develop system safety documentation.

The new complex engineering processes, which implement concepts such as “System of Systems” (SoS), require world-class specialists in system safety to ensure the highest quality along the whole V-cycle process both for aircraft level integrations and systems / components level.

Safety for the new “System of Systems” concept

The importance of including safety from the initial stages of an SoS is a key aspect to identify interdependences and hazards. Modeling and simulation should be considered from the initial stages to help identify risks before they occur. Instrumentation and data collection systems becomes more relevant than ever before. It is important to establish an interdisciplinary process for evaluation and feedback of lessons learned, as well as the Inclusion of SE (Safety) in operational organization during the phase of Systems of Systems operations.

scroll down